Carbon Fiber: Lightweight designs reshaping mobility

Discover how carbon fiber is transforming wheelchairs & mobility aids at NextGen HME. Learn about its strength, lightness, durability & explore top carbon fiber products.

Discover how carbon fiber is transforming wheelchairs & mobility aids at NextGen HME. Learn about its strength, lightness, durability & explore top carbon fiber products.

Unrivaled Lightness, Uncompromising Strength: Carbon fiber provides the structural integrity of metal with significantly less weight. This translates to easier maneuvering, reduced user fatigue, and enhanced portability – key factors for daily living.

Built for the Long Haul: Its superior resistance to wear and tear ensures that carbon fiber-based devices withstand the rigors of everyday use, offering long-term reliability and reducing the need for frequent replacements.

Smooth and Comfortable Movement: Carbon fiber effectively absorbs vibrations, minimizing discomfort and fatigue often associated with traditional mobility devices, allowing users to remain active for longer.

Durable and Hygienic: Unlike metals that can corrode, carbon fiber resists degradation from environmental factors and bodily fluids, contributing to a more hygienic and longer-lasting product.

Designed for Optimal Support: The unique moldability of carbon fiber allows for the creation of ergonomically contoured designs that provide superior support and comfort, crucial for patient compliance and therapeutic outcomes.

Myth #1: Performs poorly in cold temperatures. Fact: Carbon fiber is used extensively in aerospace applications, enduring extreme temperature variations with minimal expansion or contraction.

Myth #2: Breaks or chips easily. Fact: Carbon fiber technology has advanced significantly. When designed with proper fiber alignment, it can withstand high-impact forces.

Myth #3: Catastrophic damage is common. Fact: The strength of a carbon fiber component is directly related to its design and the way the fibers are laid. Well-engineered carbon fiber products are incredibly durable.

The Pride Mobility Go Go® Carbon Portable Scooter is the ultimate lightweight travel scooter, combining cutting-edge design with convenience.

Built with a carbon fiber frame, it offers an incredibly strong yet lightweight structure, making transportation effortless. This ultra-portable scooter folds in seconds and features an airline-compliant lithium battery, allowing for worry-free travel.

With a 300-lb weight capacity, a top speed of up to 3.7 mph, and a range of up to 10 miles per charge, the Go Go® Carbon is perfect for users who need a reliable and stylish mobility solution.

Key Features

Key specs

Couldn't load pickup availability

The ADI Carbon Fiber seatbase is a viable option for anybody looking to reduce the overall weight of their manual chair setup while still maintain consistent, solid seating.

Couldn't load pickup availability

The ByAcre Carbon Ultralight Rollator is a revolutionary mobility aid designed for active individuals. Crafted from high-strength carbon fiber, this rollator boasts exceptional strength and durability while remaining remarkably lightweight at just 10.6 lbs.

Its featherweight design makes it effortless to maneuver, lift, and transport, offering unparalleled freedom and convenience for users on the go. Whether you're navigating busy streets, traveling, or simply enjoying a leisurely stroll, the Byacre Carbon Ultralight Rollator provides the support and agility you need.

Key Features:

Couldn't load pickup availability

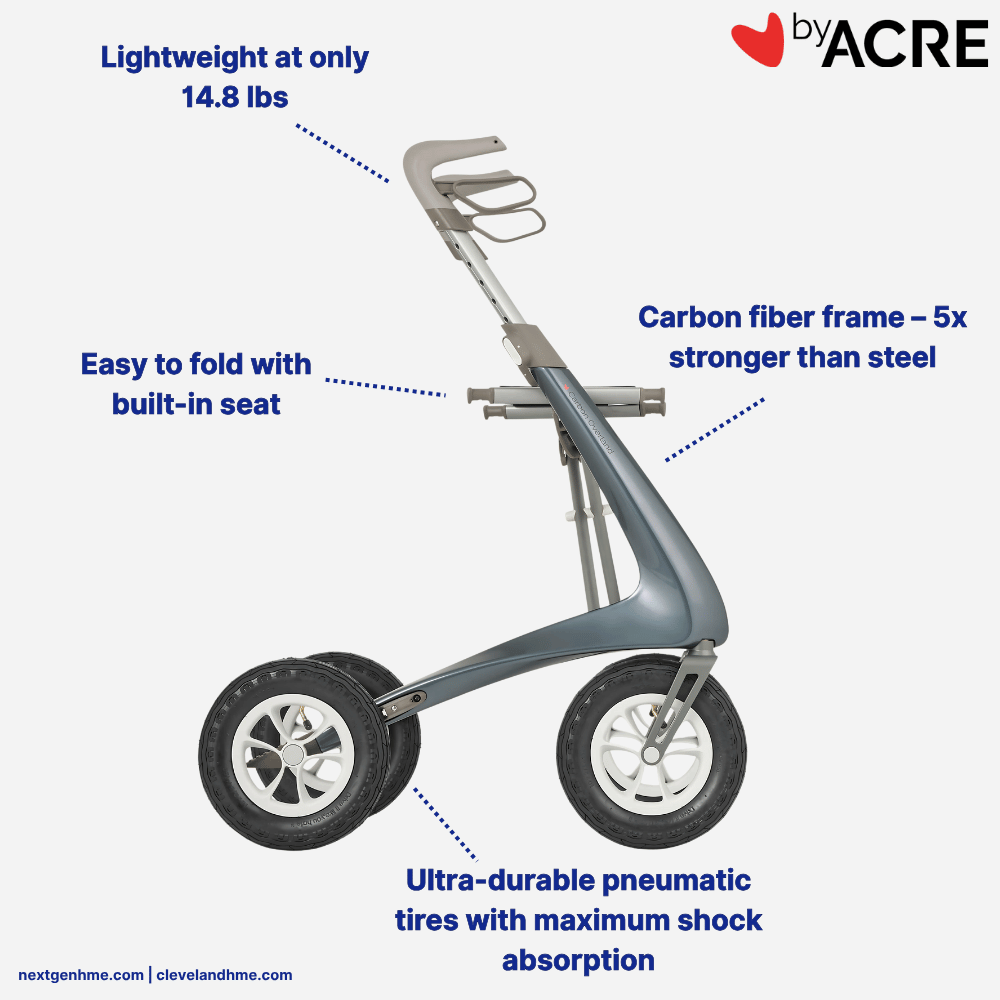

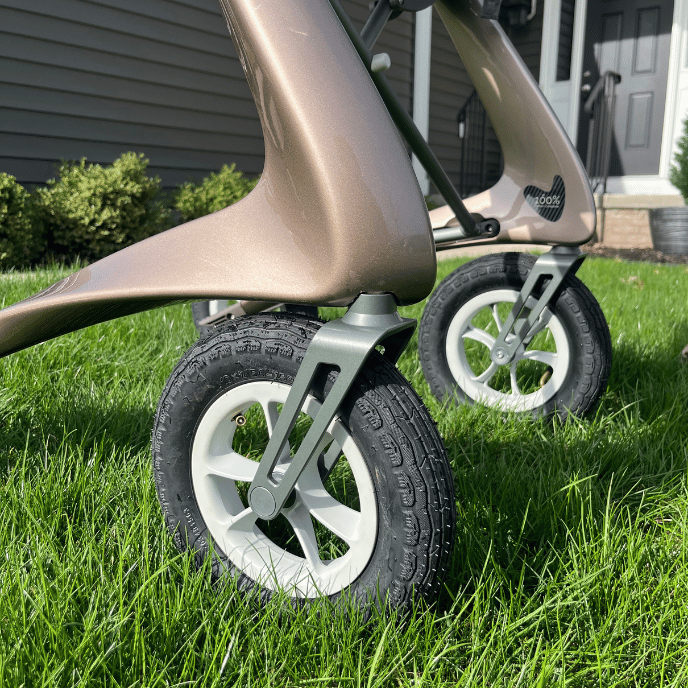

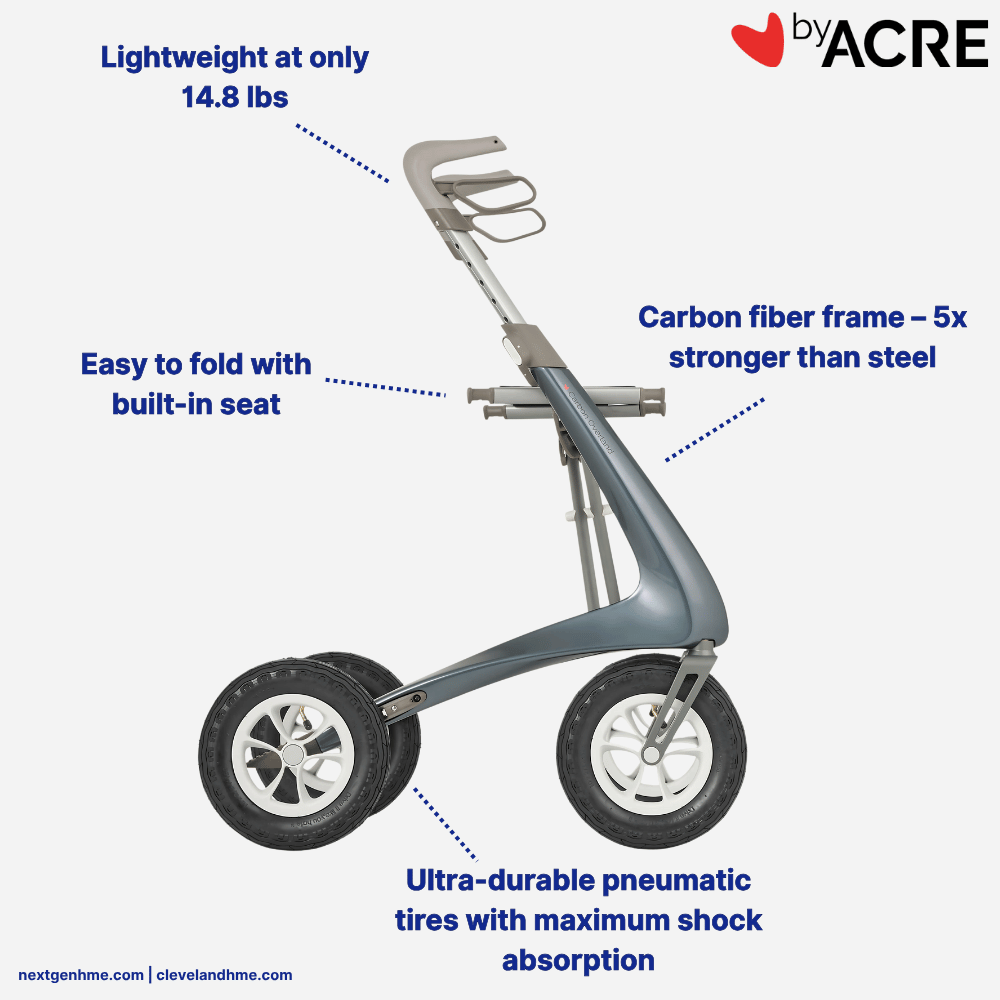

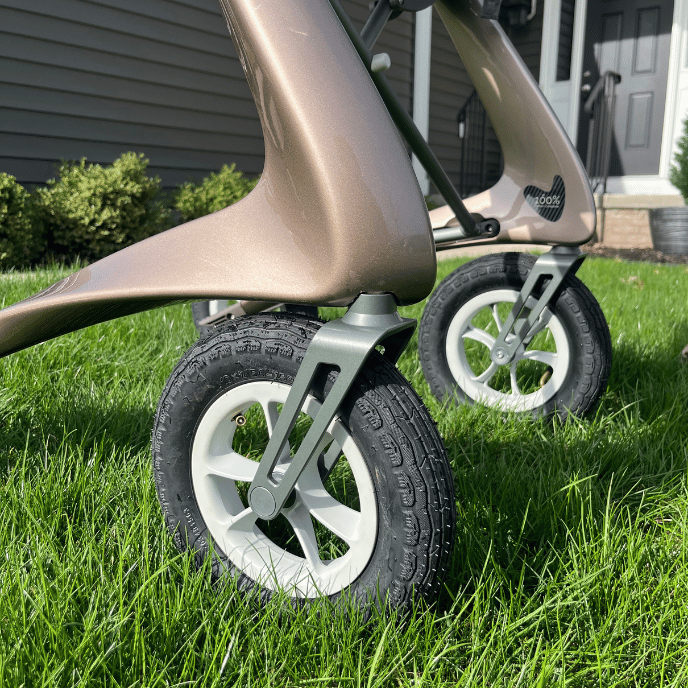

With the off-road walker Carbon Overland, it is our ambition to give you the freedom to move wherever you want - without restrictions.

With its lightweight, the strong carbon fiber frame and the solid rubber tires, you can take the Carbon Overland with you in all kinds of weather and on any terrain, so you can enjoy the outdoors.

Key Features:

Superior outdoors on grass, hills and dirt roads

Very solid, pneumatic tires with maximum shock absorption

Strong front forks and sealed bearings

Carbon fiber frame – five times as strong as steel

Weighs only 6.7 kg

Easy to fold and comes with a built-in seat

Delivered fully assembled and ready for you to explore

A companion for exploring and adventures.

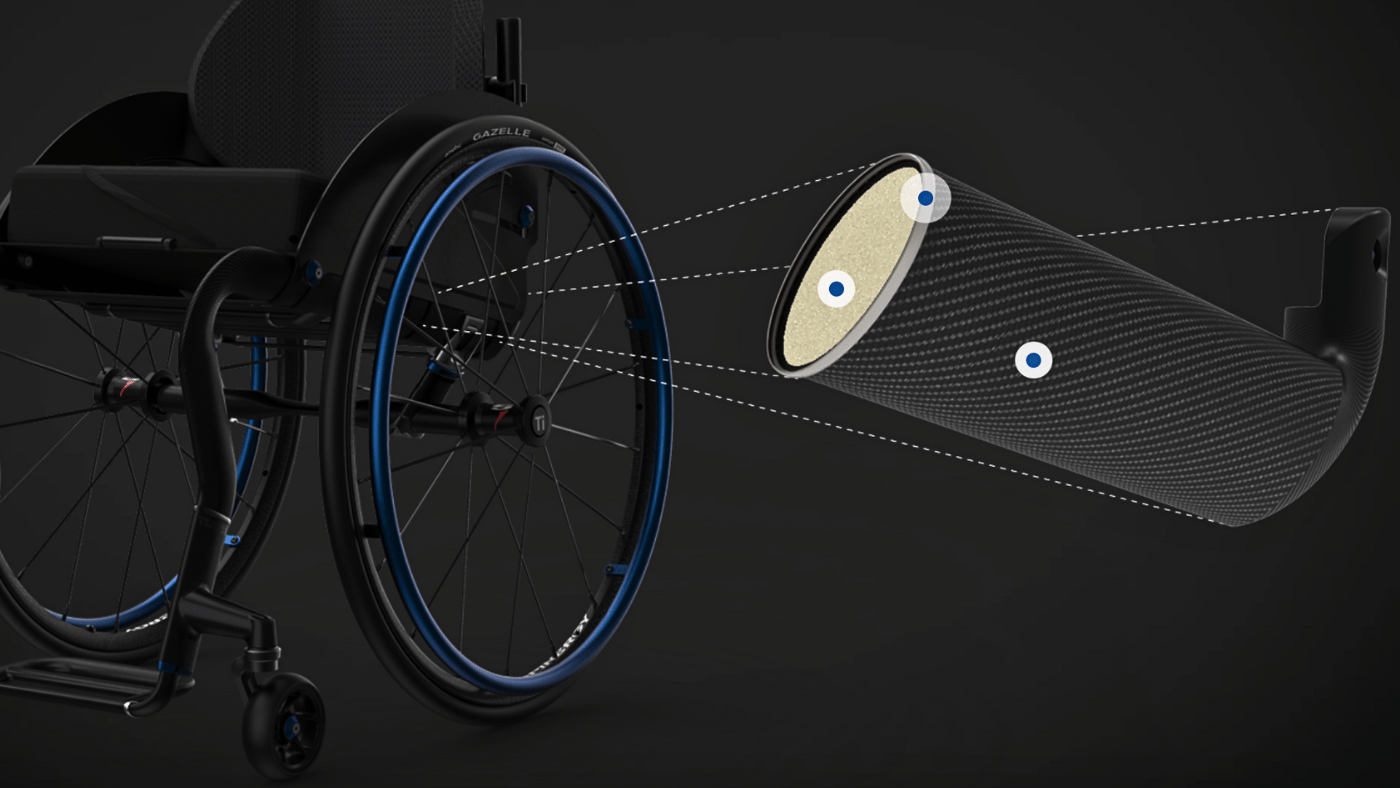

All-terrain rollator with ultra-durable pneumatic tires and superb suspension

Rigid front forks and sealed bearings that withstand every weather and terrain

Carbon fiber frame – 5x stronger than steel

Tough yet lightweight at only 14.8 lbs – for easy lifting into your vehicle

Foldable and with a built-in seat

Comes fully assembled and ready to explore

Couldn't load pickup availability

The Jazzy Carbon is the epitome of portable power. Crafted with a lightweight carbon fiber frame, this folding power wheelchair is designed for those who value both style and substance.

Key Features

✈️🔋Transport of this item on commercial aircraft is subject to federal regulations and airline policy.

Please consult your airline prior to your flight to ensure your Jazzy® Carbon and its lithium ion battery are permitted. ✈️🔋

Couldn't load pickup availability

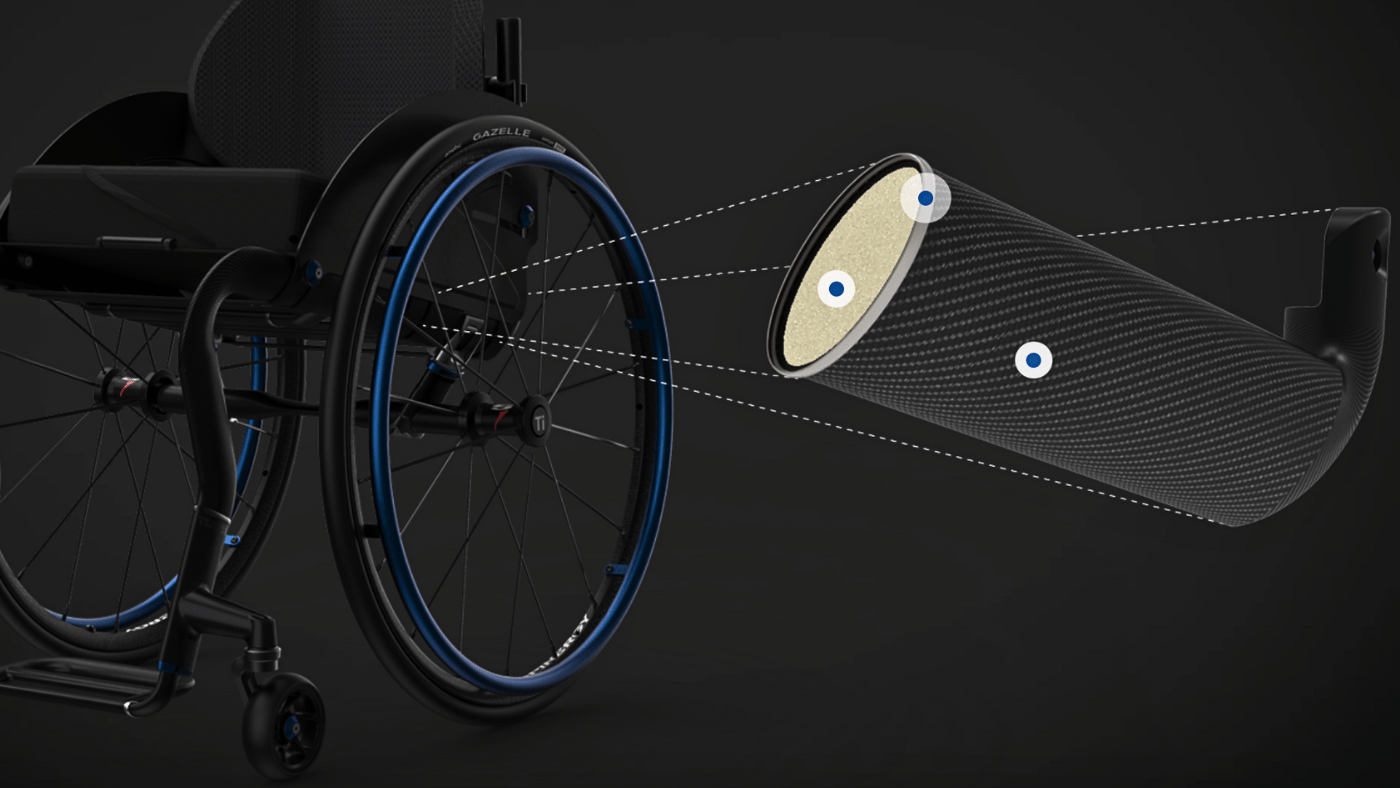

At 589 grams a wheel (1.1 LBS.) you will feel like you are floating through the air.

The Round Betty Carbon Spöke Wheel is without a doubt the best true FULL carbon fiber wheelchair wheel in the industry.

A classy super high performance top-of-the-line wheel using only the highest carbon fiber technology.

The fixed spoke design means no loose spokes needing to be tightened or replaced. Complete performance, strength and durability for everyday use. Accept no substitutes when it comes to the best.

Key Features

Couldn't load pickup availability